Exploring the Impact of Cocoa Machines on Global Trade at the 2025 China Import and Export Fair

As the global demand for cocoa products continues to rise, the significance of cocoa machines in facilitating efficient processing and trade has become increasingly evident. According to a report by Research and Markets, the global cocoa processing market is projected to reach approximately $10 billion by 2026, driven by growing consumer interest in chocolate and related products. The upcoming 2025 China Import and Export Fair, also known as the 138th Canton Fair, is poised to showcase the latest innovations in cocoa machines that cater to this demand.

By exploring the impact of these advanced machines on global trade dynamics, we can better understand their role in enhancing productivity, ensuring product quality, and meeting the stringent sustainability requirements of modern consumers. As countries around the world look to improve their cocoa production capabilities, the integration of state-of-the-art cocoa machines will undoubtedly be a pivotal factor in shaping future market trends.

The Role of Cocoa Machines in Enhancing Production Efficiency

As the world shifts towards automation, cocoa machines are revolutionizing the production processes within the cocoa industry. By enhancing production efficiency, these machines play a crucial role in meeting the growing global demand for cocoa products. Advanced cocoa processing machines not only streamline operations but also reduce labor costs and minimize wastage. This enables manufacturers to produce high-quality products at a faster pace, allowing them to compete effectively in the international market.

Tips for Cocoa Machinery Usage:

Investing in top-notch cocoa machines ensures consistency in product quality. Regular maintenance checks are also essential to maximize machine longevity and performance.

Additionally, training staff to effectively operate these machines can lead to better utilization and further increases in productivity.

Moreover, cocoa machines facilitate a more sustainable approach to production. Automated systems can monitor parameters such as temperature and humidity, ensuring that the cocoa beans are processed under optimal conditions. This level of precision not only improves yield but also helps in preserving the rich flavor and quality that cocoa lovers cherish. With the rise of eco-conscious consumers, such efficiency coupled with sustainability positions cocoa producers for success in the competitive global trade landscape.

Global Trade Trends: Cocoa Machine Demand in Emerging Markets

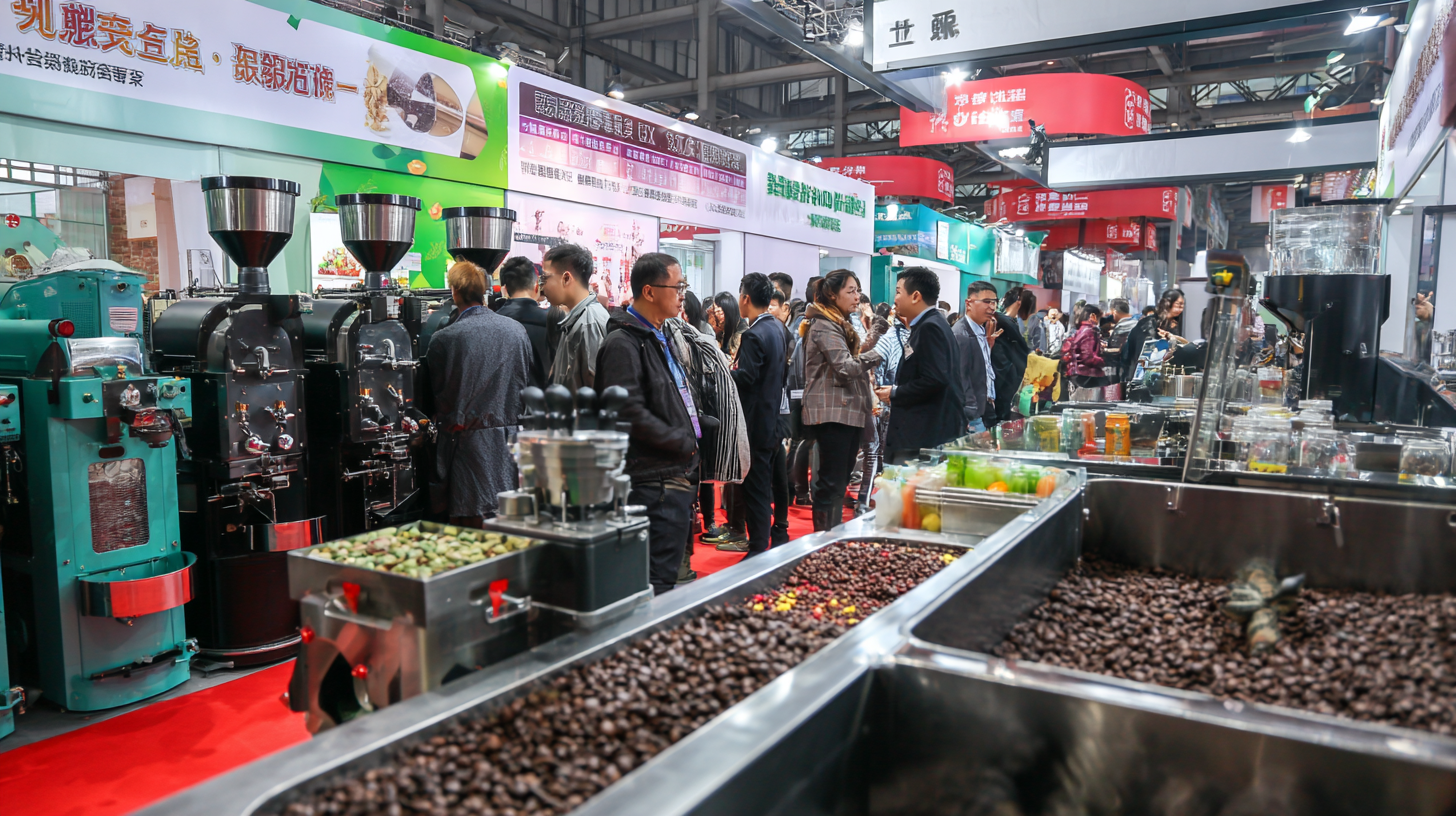

The demand for cocoa machines in emerging markets is witnessing remarkable growth, driven by the increasing popularity of chocolate products and the rising consumer preferences for high-quality confectionery. Countries in Asia, Africa, and South America are significantly ramping up their cocoa production capabilities to meet both local and international demand. At the 2025 China Import and Export Fair, industry players will have the opportunity to explore innovative cocoa processing technologies that can help them capture a larger market share.

**Tips for Engaging in Emerging Markets**: Understanding local consumer preferences is crucial for success. Tailoring cocoa machine features to suit regional tastes can greatly enhance product acceptance. Additionally, building partnerships with local distributors can improve the supply chain efficiency and reduce market entry barriers.

As cocoa consumption rises, manufacturers are capitalizing on the trend by investing in advanced machinery that promises not just efficiency but also sustainability. By attending the fair, businesses can gain insights into cutting-edge technologies that facilitate sustainable cocoa processing, which is gaining traction among environmentally conscious consumers.

**Tips for Sustainability**: Always consider the environmental impact of cocoa production. Machines that reduce energy consumption and waste can attract eco-friendly buyers, further enhancing market competitiveness.

Global Cocoa Machine Demand Trend in Emerging Markets (2020-2025)

Impact of Technological Advancements on Cocoa Processing

Technological advancements in cocoa processing have significantly transformed the cocoa industry, enhancing productivity and efficiency. At the 2025 China Import and Export Fair, the spotlight will be on innovative cocoa machines designed to streamline processing operations. These developments not only improve the quality of cocoa products but also reduce waste and energy consumption. Modern cocoa processing technologies, such as automated roasting, grinding, and fermentation systems, allow manufacturers to produce high-quality cocoa beans and chocolate more efficiently, catering to the growing global demand.

Moreover, the integration of artificial intelligence and data analytics into cocoa processing is reshaping the landscape of the industry. These technologies enable real-time monitoring of processing conditions, leading to optimized production cycles and consistent product quality. As cocoa machines evolve, they also contribute to the sustainability of cocoa farming by minimizing environmental impact and promoting fair trade practices. The advancements brought forth by these technologies not only influence production capabilities but also play a crucial role in enhancing the competitiveness of cocoa producers in the global market.

Sustainability in Cocoa Machinery: Meeting International Standards

Sustainability in cocoa machinery is becoming increasingly significant as global demand for cocoa products rises. The cocoa industry is under pressure to adopt greener practices, and machinery plays a crucial role in this transition. According to a recent report by the International Cocoa Organization, the global cocoa market is expected to grow at a CAGR of 4.5% from 2021 to 2026, prompting manufacturers to invest in equipment that minimizes environmental impact. Sustainable cocoa machines not only help in reducing carbon footprints but also ensure compliance with international standards like ISO 14001.

Tip: When selecting cocoa machinery, consider options that offer energy efficiency and low emissions. This choice not only aids in sustainability efforts but also contributes to cost savings in the long run.

Moreover, the emphasis on sustainability is not merely a trend but a necessity driven by both consumer preferences and regulatory requirements. Data from the Cocoa Sustainability Partnership indicates that 70% of consumers are willing to pay more for products from environmentally responsible brands. Therefore, cocoa machinery that meets stringent sustainability criteria is becoming an essential investment for companies aiming to remain competitive in the global market.

Tip: Regular maintenance of cocoa machines can enhance their efficiency and longevity, further supporting sustainable practices while optimizing production outputs.

Case Studies: Successful Cocoa Enterprises at the 2025 Import and Export Fair

As the global demand for cocoa continues to rise, with the International Cocoa Organization (ICCO) reporting a yearly increase of approximately 2% in consumption, enterprises participating in the 2025 China Import and Export Fair are embracing innovative cocoa machines to enhance their production efficiency. Notably, these machines streamline processes from grinding to tempering, significantly reducing production time and costs. For instance, one cocoa processing company showcased at the fair utilized advanced grinding technology that cut processing time by 30%, allowing them to meet the increasing demand in competitive markets.

Moreover, several successful cocoa enterprises highlighted during the fair have reported substantial growth in export opportunities attributed to their use of state-of-the-art processing equipment. For example, a prominent cocoa exporter noted a 50% increase in orders after integrating automated quality control measures, ensuring that their products consistently meet international standards. The fair served as a platform for these businesses to share insights and strategies, with many attendees emphasizing that adopting such technologies not only boosts productivity but also enhances the overall quality of cocoa products, positioning them favorably in the global market.

Related Posts

-

How to Choose the Right Cocoa Machines for Your Business Needs

-

What is the Innovation Behind Selmi Chocolate Machine Technology

-

Unlocking the Advantages of Chocolate Panning Machines for Your Confectionery Business

-

Exploring the Alternatives to Traditional Hot Chocolate Machines for Your Beverage Business

-

How to Select the Best Chocolate Panning Machine for Your Production Needs

-

Top Strategies for Enhancing Efficiency with Chocolate Wrapping Machines