How to Choose the Best Chocolate Enrobing Machine for Your Business

As the global chocolate market continues to expand, with a projected value of over $161 billion by 2024 according to a report by Market Research Future, the demand for efficient and high-quality production processes has never been more critical. For businesses looking to enhance their chocolate production capabilities, choosing the right chocolate enrobing machine is a vital step. These machines not only improve the efficiency of coating confections but also ensure a consistent and professional finish that can elevate the product quality to meet consumer expectations.

The chocolate enrobing machine market is witnessing significant growth, driven by increasing consumer preferences for innovative chocolate products and the rising trend of artisanal and personalized confections. Furthermore, research from Allied Market Research indicates that the confectionery segment, which includes enrobed products, is experiencing a surge in demand, especially in developed regions where chocolate consumption is consistently on the rise.

With this booming market, selecting the appropriate enrobing machine tailored to your business's specific needs can result in improved production efficiency and enhanced product appeal, setting your brand apart in a competitive landscape.

In an era where automation and technology are paramount for maintaining a competitive edge, understanding the intricacies of chocolate enrobing machines becomes essential for business owners. Whether it be the size, technical specifications, or production capacity, making an informed choice will not only streamline your operations but also position your products to satisfy an increasingly discerning consumer base.

Understanding Chocolate Enrobing Machines and Their Functionality

Chocolate enrobing machines are essential for businesses looking to streamline the process of coating confections in chocolate. These machines come in various sizes and designs, each catering to different production needs. At their core, enrobing machines function by efficiently coating products, such as biscuits or candies, with a layer of melted chocolate, ensuring uniformity and high-quality coatings. The machine typically includes a conveyor system that transports the items through a chocolate waterfall, allowing for optimal coverage and minimal waste.

Understanding the functionality of chocolate enrobing machines involves recognizing key features that enhance their efficiency. Temperature control is crucial, as it maintains the ideal consistency of chocolate, preventing it from becoming too thick or too thin. Furthermore, the speed settings of the conveyor belt can be adjusted to accommodate different sizes and types of products, ensuring a versatile operation. Some advanced enrobing machines also come equipped with additional functions like cooling tunnels, which quickly set the chocolate coating for a polished finish.

Selecting the right machine that meets these functional requirements can significantly impact production quality and overall business success.

Key Factors to Consider When Selecting an Enrobing Machine

When selecting the best chocolate enrobing machine for your business, several key factors must be taken into consideration to ensure an efficient and cost-effective operation. One major aspect is the production capacity of the machine. According to a recent industry report by the Research and Markets Group, the global chocolate processing equipment market is expected to exceed $5 billion by 2026, driven by rising demand for premium and artisanal chocolates. Thus, businesses should assess their output requirements and choose a machine that can meet or exceed these volumes to maintain competitiveness.

Another critical factor is the machine's technology and features. Modern enrobing machines are equipped with advanced temperature control systems, adjustable speed settings, and easy-to-use interfaces, which significantly enhance the enrobing process. A study by the Chocolate Manufacturers Association highlighted that machines with precise temperature control can improve chocolate quality by up to 30%, reducing spoilage and ensuring a better finish. Additionally, businesses should evaluate the machine’s ease of maintenance and cleaning, as these aspects can affect production downtime and overall operational efficiency. By considering these factors carefully, you can select an enrobing machine that meets your business needs and supports growth in the dynamic chocolate market.

How to Choose the Best Chocolate Enrobing Machine for Your Business

| Factor | Description | Importance | Price Range |

|---|---|---|---|

| Production Capacity | The amount of product that can be enrobed per hour. | High | $15,000 - $50,000 |

| Temperature Control | Effectiveness of controlling the chocolate temperature during enrobing. | Medium | $10,000 - $40,000 |

| Ease of Cleaning | How easy it is to disassemble and clean the machine. | High | $8,000 - $30,000 |

| Materials Used | Quality of materials used in the construction of the machine. | High | $12,000 - $45,000 |

| Size and Footprint | The physical dimensions of the machine and space requirements. | Medium | $7,000 - $25,000 |

| Customization Options | Ability to customize settings and features based on business needs. | Medium | $10,000 - $35,000 |

Evaluating Production Capacity and Efficiency Requirements

When selecting a chocolate enrobing machine for your business, evaluating production capacity and efficiency requirements is critical. According to a recent industry report, the global chocolate enrobing machine market is projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2028, driven by the increasing demand for chocolate products and innovations in processing technology. Businesses must assess their expected output, as machines can vary significantly in capacity—ranging from 50 kg/hr for small-scale operations to over 500 kg/hr for larger manufacturers. This assessment ensures that the chosen machine can meet production demands without bottlenecks.

Efficiency is another essential factor to consider. A study published by Food Processing Technology highlights that modern enrobing machines can achieve up to 90% efficiency compared to older models, which only reached around 70%. This improvement not only enhances production speed but also reduces waste, allowing companies to maximize profit margins. Additionally, investing in equipment with advanced features—such as automated temperature control and customizable coating thickness—can lead to higher quality products, ultimately strengthening market position. By prioritizing both capacity and efficiency, businesses can make informed decisions that support their growth and competitive edge.

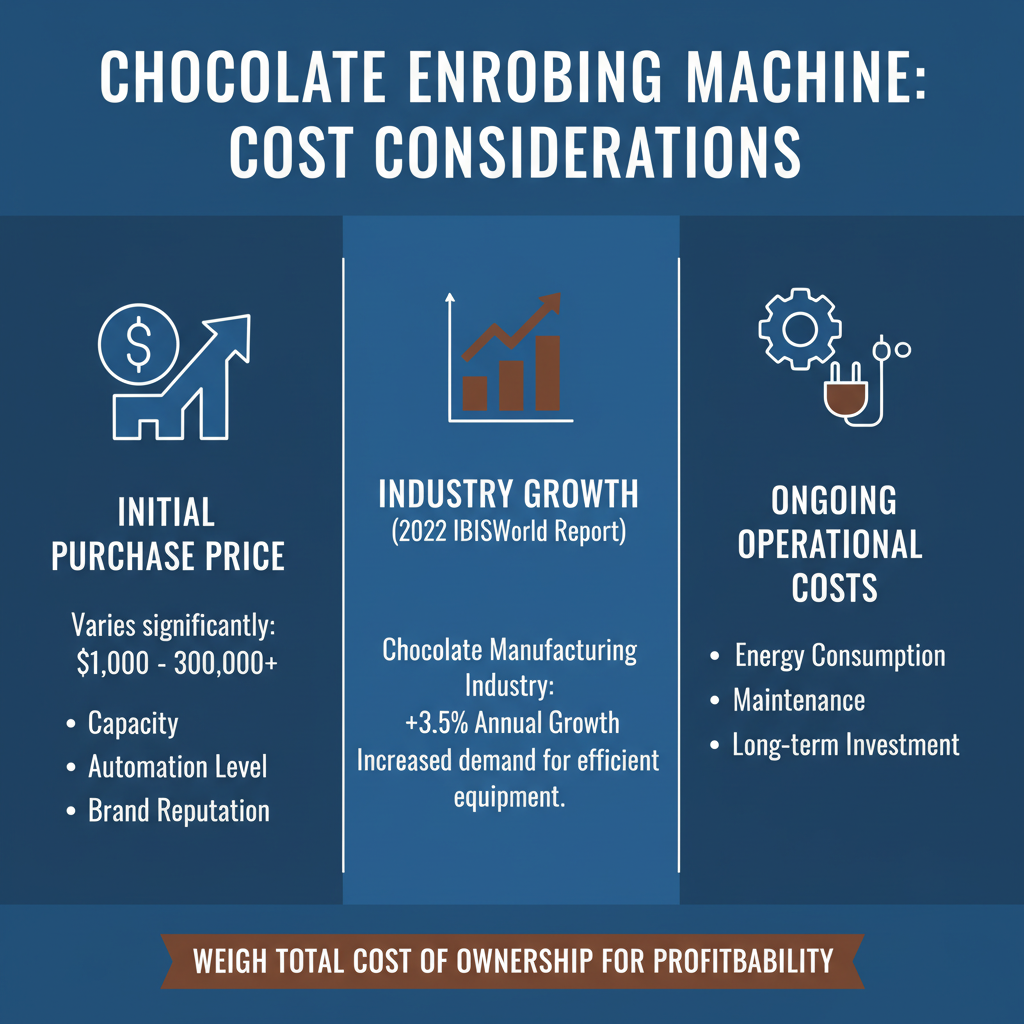

Assessing Budget and Cost Considerations for Enrobing Equipment

When selecting the best chocolate enrobing machine for your business, budget and cost considerations play a crucial role. The initial purchase price of enrobing equipment can vary significantly, ranging from $10,000 to over $300,000, depending on the machine's capacity, automation level, and brand reputation. According to a 2022 report by IBISWorld, the chocolate manufacturing industry is projected to grow at an annual rate of 3.5%, increasing demand for efficient production equipment. Businesses must weigh not just the purchase price but also ongoing operational costs, such as energy consumption and maintenance.

Additionally, enterprises should consider the potential return on investment (ROI) when evaluating enrobing machines. A well-chosen machine can significantly enhance production efficiency and product quality, leading to higher sales and customer satisfaction. The same IBISWorld report highlights that companies investing in advanced technology, including automated enrobing systems, can reduce labor costs by up to 20% while increasing output by 15%-25%. By focusing on both the upfront costs and long-term operational expenses, businesses can make informed decisions that align with their growth strategies and financial constraints.

Comparing Features and Specifications of Different Models

When selecting the best chocolate enrobing machine for your business, it's essential to compare the features and specifications of different models. One key aspect to consider is the production capacity, as many manufacturers report that machines with a capacity of producing 600 kg per hour are ideal for medium-sized businesses, while larger operations may require machines that can handle over 1,000 kg per hour. According to a recent market analysis by Research and Markets, the global chocolate processing equipment market is expected to grow at a CAGR of 4.8% between 2023 and 2028, emphasizing the importance of investing in high-quality enrobing machinery to keep pace with increasing demand.

Another critical feature to evaluate is temperature control and consistency. Advanced models incorporate precise temperature regulation systems that maintain chocolate quality and reduce wastage due to overheating. Industry surveys indicate that machines with integrated cooling tunnels significantly improve the cooling process, reducing the overall enrobing time by up to 20%. Additionally, consider the ease of cleaning and maintenance, as machines with removable parts and automatic cleaning features are preferred due to the stringent hygiene standards in food processing. With the right combination of features, your investment in a chocolate enrobing machine will enhance production efficiency and product quality.

Related Posts

-

Unlocking the Advantages of Chocolate Panning Machines for Your Confectionery Business

-

How to Select the Best Chocolate Panning Machine for Your Production Needs

-

What is a Confectionery Machine and How Does It Transform Candy Production

-

Unleashing Creativity: How a Chocolate Drink Maker Transforms Simple Ingredients into Gourmet Delights

-

How to Choose the Right Cocoa Machines for Your Business Needs

-

What is a Chocolate Packaging Machine and How Does It Work